IET, Inc.

Industrial Engineering Services

Industrial Engineering Services

Our Services

IET is a full service industrial and manufacturing engineering firm. We serve as engineering and manufacturing consultants in addition to providing hands-on support. With a comprehensive range of capabilities from business process reengineering to plant layout analysis, we improve our clients' competitiveness.

All our projects begin with identifying our clients' objectives and the role we can play in obtaining those goals.

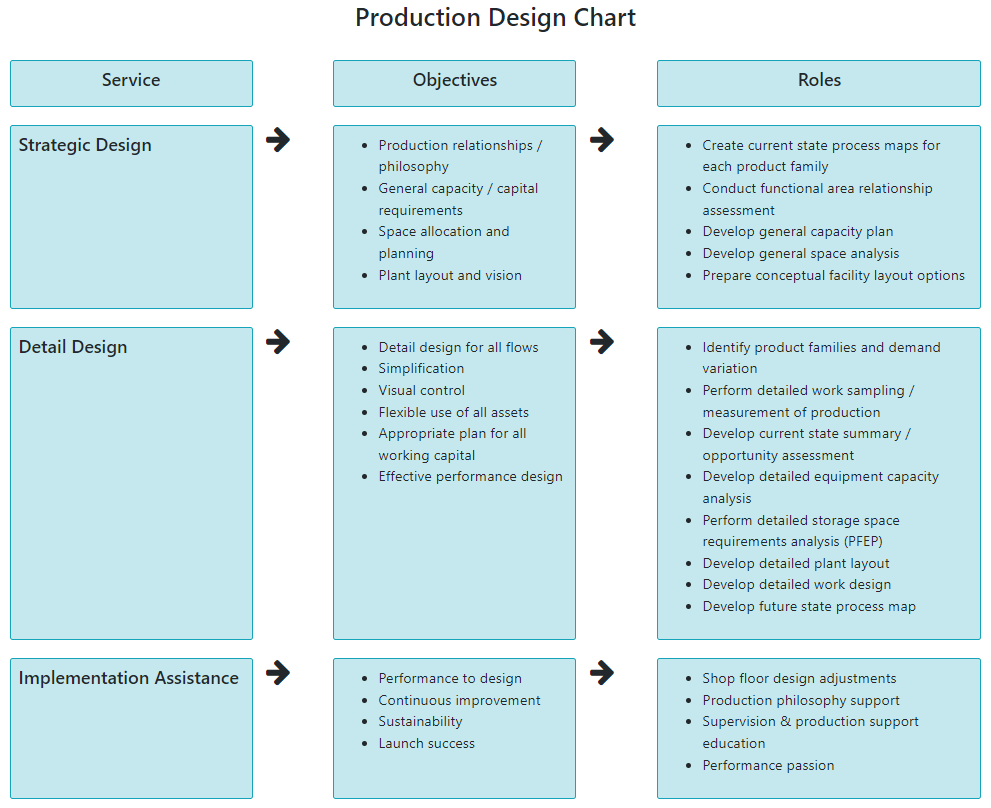

Our general Production Design Chart is shown below.

If you can answer "No" to any of the following questions, IET can help you!

We can assist you with your current or proposed facility layout in the following areas:

If you can answer "No" to any of the following questions, IET can help you!

We can provide work measurement utilizing the appropriate tools for the client's needs.

If you can answer "No" to any of the following questions, IET can help you!

We can provide a complete project management package. This may include preparing and presenting reports to your customer, monitoring the progress of your suppliers, preparing and following up on action plans and general coordination of any of the project's activities.

If you can answer "No" to any of the following questions, IET can help you!

We can assist with your production planning needs in a variety of ways:

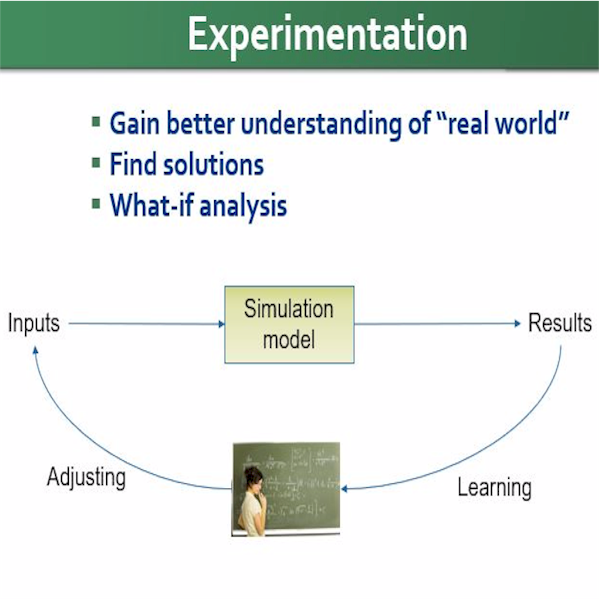

If your production system is difficult to model in a spreadsheet because of the many variations or you need to get your entire production team on the same page regarding your new design, simulation may be the tool to help you.

Our custom simulation models can be used to evaluate various equipment arrangements, material handling alternatives, labor balancing, assembly line sequencing and more.

Common areas of analysis include the following:

If you can answer "Yes" to any of the following questions, IET can help you!

We partner with Nysus Solutions to provide the Manufacturing Execution System (MES). MES is a web application framed around quality assurance through providing automated work instructions. The MES system interfaces with PLCs and Databases in order to provide feedback to the operator even where feedback has not been readily available before.

If you can answer "Yes" to any of the following questions, IET can help you!

We can provide a wide variety of engineering staffing solutions to meet your needs. From quality engineering, mechanical engineering, project management, production and maintenance supervision, we can provide solutions to your needs on a short or long-term basis. We have the expertise to provide contract engineering support across all industries.

IET can provide contract support in the following areas:

Would Industrial Engineering training provide consistency throughout your organization? We offer the following group training in your facility

In addition to our Industrial Engineering solutions, we also offer Quality Engineering and Process Improvement services and provide a hands-on approach to assist in development of, and/or implementation of, your Quality Management or Continuous Improvement projects.

We provide Quality Engineering services including all facets of the APQP process from product inception through the entire PPAP process and on to successful production launches. Have an upcoming audit? We can help with gap analysis, authoring or updating policies or procedures and employee training. We have experience with TS-16949, the ISO 9000 standards and ISO/IEC 17020 as well as many OEM requirements.

We can also provide assistance with process improvements and problem solving. We can help you solve problems, reduce waste and improve your processes using Six Sigma and Lean Manufacturing tools to identify root cause, choose the appropriate corrective action and, most importantly, put in place a sustainable preventive action to prevent recurrence.

So whether you need Industrial Engineering or Quality Engineering services to supplement existing efforts, IET has the resources, knowledge and experience to be your one-stop solution destination for your next project or to meet quickly approaching deadlines.